Inspection

We offer thorough inspection services to ensure the quality and compliance of your products. Our expert team conducts detailed inspections per the approved project ITP and provides comprehensive reports, ensuring that your products meet the highest standards.

We offer independent shop inspections across various industrial fields, covering the following key operational steps:

Pre-assessment & Supplier Selection: Evaluating and selecting the best suppliers to ensure quality and reliability.

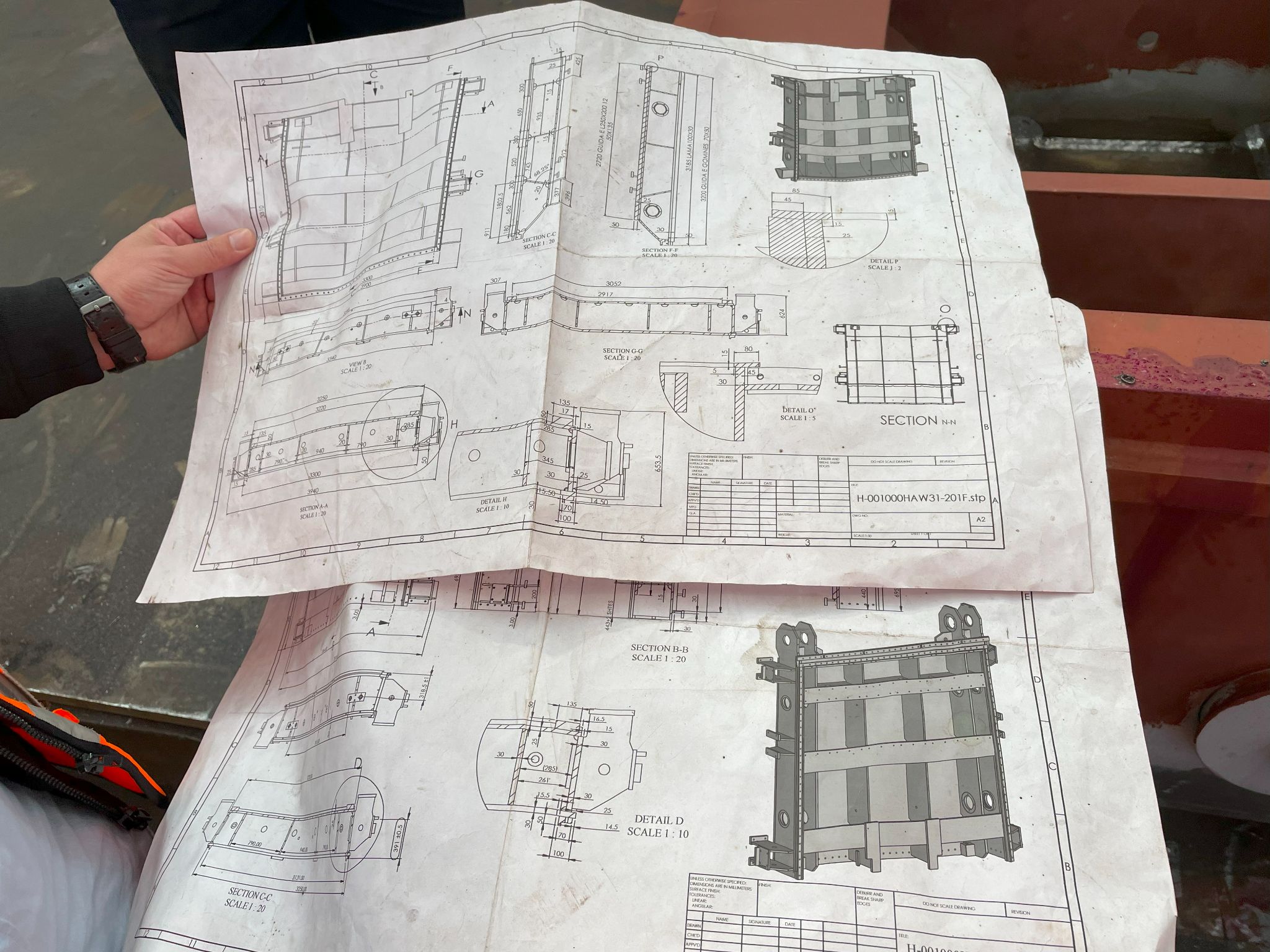

Fabrication: SEI Global provides comprehensive fabrication inspection services to ensure adherence to project specifications and international standards. Our experienced inspectors oversee every stage of the fabrication process, ensuring quality, reliability, and compliance. Key aspects of our fabrication inspection services include:

Welding Procedure Qualification (WPQ):

We ensure that welding procedures are thoroughly qualified according to applicable codes and standards. Our services include reviewing and validating welding procedure specifications (WPS) to guarantee compatibility with project requirements and material specifications.

Welder Qualification:

Our experts assess and qualify welders to confirm their ability to perform specific welding tasks according to industry codes and project needs. This includes practical testing to validate skills and adherence to approved procedures, ensuring top-notch weld quality in all fabrication stages.

Non-Destructive Testing (NDT) Services:

We utilize advanced NDT techniques to assess the integrity and quality of materials and welds without causing damage. Methods include ultrasonic testing, radiographic testing, magnetic particle testing, and dye penetrant testing, ensuring defects are identified and addressed promptly.

Destructive Testing Services:

To validate material properties and weld quality, we offer destructive testing, including tensile testing, impact testing, and bend testing. These methods provide critical insights into the performance and durability of materials under various conditions.

Paint Inspection Services:

We conduct thorough inspections of surface preparation, coating application, and curing processes to ensure compliance with specifications and industry standards. Our services include monitoring environmental conditions, verifying coating thickness, and identifying defects to guarantee optimal corrosion protection and durability.

Packaging: Ensuring proper packaging to protect materials and products during transit